Lifespan Tests

Lifespan tests are performed with and without electrical load on the main circuit of the device being tested. These tests are controlled and monitored automatically and run in continuous 24-hour operation. Within this context, manually actuated devices are actuated mechanically or pneumatically, while electromechanical devices are run with the required control voltage. Finally, the operating frequency is up to 10,000 switching operations per hour.

The electrical lifespan of devices is determined under electrical load, and I²PS has an extremely powerful system that makes it possible to perform service life tests with currents of up to 9,600 A at test voltages of up to 1,000 V.

Have a look at our Lifespan flyer.

|

A device's electrical lifespan is determined with the corresponding main circuit under electrical load. For this test, I²PS has an extremely powerful system that makes it possible to perform lifespan tests with currents of up to 9,600 A at test voltages of up to 1,000 V with a high number of switching operations (switching frequency of up to 1,000 operations per hour) around-the-clock.

Our electrical life tests meet e.g. the requirements for the following utilization categories: AC1, AC2, AC3, AC4, AC15 as well as DC1, DC3, DC5 and DC13.

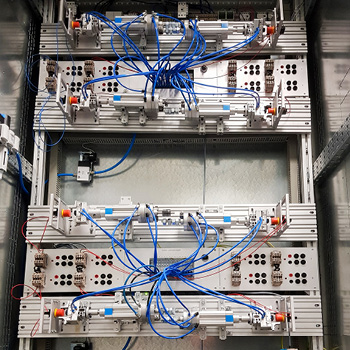

We have ca. 30 testing stations for these long-term tests with automated DUT monitoring.

Please ask for our special terms and conditions for long-term test offerings!

|

Relevant Standards: |

|

A device's mechanical lifespan is determined with no electrical load on the corresponding main circuit. For this test, I²PS has testing systems that can actuate various manually driven devices. And in addition to the usual mechanical and pneumatic operating elements, there is also the option of using electrical linear actuators in order to implement a flexible actuation configuration and, if necessary, obtain additional measurements during actuation.

I²PS has testing stations for more than 100 devices, up to 48 stations being equipped with linear actuators. Speeds of 0.05 to 0.15 m/s, with load cells and displacement measurements if necessary, can be used within this context.

4x8 test stations have a pneumatic drive. All possible mounts and types of monitoring are offered.

|

Relevant Standards: |

|

The decisive parameter for assessing the reliability of a component subject to wear is the so-called B10 value.

The B10 value for components subject to wear, such as a relay, is expressed in number of switching cycles. This is the number of switching cycles at which 10% of the test specimens have failed in the course of a service life test. Parameters such as switching current, switching voltage and load type play a significant role here.

The determination of the B10 value is originally a requirement from mechanical engineering EN / ISO 13849.

I2PS offers such tests on electromechanical components as endurance tests at customized, individual conditions.

|

Relevant Standards: |