Mechanical tests

In addition to the electrical suitability and the resistance to environmental conditions, the mechanical properties of both devices and their components are crucial when it comes to operation and service life. A device can be subjected to an extremely wide variety of mechanical loads throughout its lifecycle. I2PS offers a variety of testing methods that make it possible to determine mechanical characteristic values or to check the mechanical strength of components, devices, and material specimens.

|

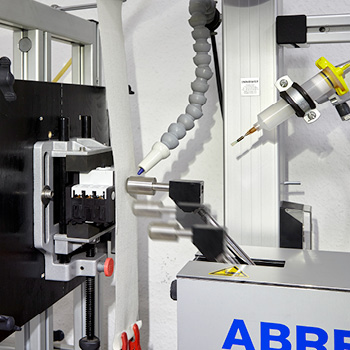

Plates, labels, and markings are often subjected to special abrasive loads throughout a device's lifecycle. It goes without saying that these markings and labels need to remain legible throughout the entire lifecycle to make it possible to identify the corresponding devices and to read safety and operating information (labels must be smear-proof and indelible, for example). Accordingly, we offer standardized manual and automated abrasion tests for labels, markings, and prints. Upon request, these tests can be combined with the application of cleaning agents and other solvents. All these tests are performed and evaluated by employees with years of experience.

|

Relevant Standards: |

|

When combined with the influence of temperature and/or other ambient conditions such as humidity, static loads can damage materials after extended periods of time (e.g. as a result of creep) even if they do not result in short term failure . This behavior can be tested with reproducible creep tests.

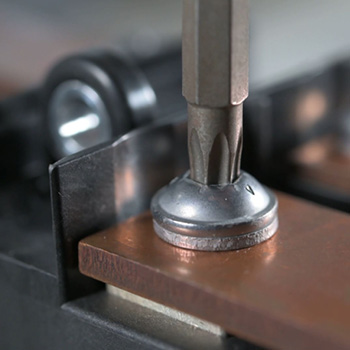

For example, a ball pressure test can be used to determine the dimensional stability of plastic specimens at elevated temperatures by subjecting the specimens to a static load exerted by a steel ball. In this case, the indentation left after the test serves as an indicator of the plastic's dimensional stability under heat. Gasket materials (elastomers) used in electrical devices requiring UL certification must successfully pass the gasket test specified in UL 50E. Among other things, this test is used to examine the materials' behavior under static pressure, as well as their resilience.

When exposed to certain chemicals, some thermoplastics (e.g. polycarbonate) are prone to stress cracking when subjected to a static load. This can be tested with a stress cracking test in which the surface of a component or a material specimen under mechanical stress is brought into contact with a chemical that triggers stress cracking. Afterwards the component or specimen is checked for stress cracks. Stress cracking tests are also used for metal specimens. Examples include stress cracking tests on brass parts and strain testing on hardened steel parts in order to check for hydrogen embrittlement.

Our highly qualified personnel will be more than happy to assist you with any of these issues and tests and can use our comprehensive testing equipment to perform these tests for you. As we regularly and successfully participate in international interlaboratory comparisons, we are able to always guarantee consistently high quality standards.

|

Relevant Standards: |

|

Our torque test stand enables us to accurately measure torques and angles of torsion. This test can be used, for example, to determine screw-in torques, tightening torques, and overtightening torques for fasteners; actuation torques for switches; and torques that will lead to the failure of control elements or mounts. In addition, the test stand makes it possible to set exact torques in order to perform reproducible tests, such as testing for the likelihood of stress cracking on components and materials (stress cracking test), or examinations of relaxation processes.

The test stand is able to accurately measure and set torques of 0 to 200 Nm.

|

Relevant Standards: In addition to customer-specific specifications, various national and international standards such as: |

|

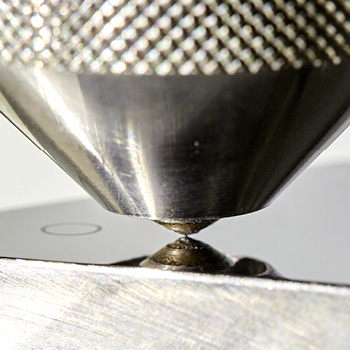

Hardness is one of the defining properties of a material and its treatment, and can be determined with suitable hardness tests that are not only generally fairly straightforward and easy to perform, but that also make it possible to obtain a quick initial assessment of a material's strength. We are able to examine the surface hardness of materials ranging from metals to elastomers. After the appropriate metallographic specimen preparation, we are also able to examine core hardnesses, hardness penetration depths [CHD, NHD, SHD, EHT, RHT, etc.], weld hardnesses, heat-affected zones, hardness profiles, and other aspects related to hardness. Depending on the specific requirements, we can use Vickers (HV0.1 to HV10), Brinell, Knoop, or Shore A, D hardness testing methods.

Simply contact us for your testing needs!

|

Relevant Standards: In addition to customer-specific specifications, various national and international standards such as: |

|

Impact tests are used to test and classify (e.g., IK code) the protection of a metal or plastic enclosure against dynamic mechanical loads. Within this context, the corresponding impact energy is transmitted in a variety of manners depending on the standard being used, with a drop hammer, spring-operated impact hammer, and pendulum impact tester being some examples. In fact, the type of impact element that needs to be used is defined in detail in the relevant standard (material, shape, dimensions, weight, etc.). In addition to impact tests, drop tests (e.g., ball drop tests) from a defined height onto products with and without outer packaging can be performed the way they are described in a variety of testing and product standards.

Finally, we perform impact tests not only on components and devices, but also on specimens in order to determine the characteristic values of the corresponding material. Within this context, we particularly use Charpy and Izod impact tests, which measure energy absorption during an impact test with a pendulum impact tester on notched or unnotched specimens.

|

Relevant Standards: |

|

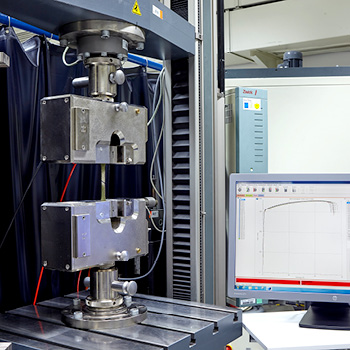

Within the context of mechanical testing, tensile, compression, and bend tests make it possible to determine important mechanical characteristic values of materials, components, and devices relatively quickly. In the case of material tests, this makes it possible to test metals and plastics in order to determine their tensile, compressive, or flexural strength, including the corresponding moduli and yield strength, elongation at yield, outer fiber strain, secant moduli, ultimate elongation at break, and apparent interlaminar shear strength (ILSS, ILSF). The tests can be performed under laboratory conditions or in a test chamber that incorporates specific temperature conditions.

In addition to standardized material tests conforming to the relevant national or international standards, we can also develop custom testing solutions designed to examine the mechanical properties of your specific devices or components (e.g., in order to determine spring characteristics, enclosure strengths, changes to mechanical properties resulting from environmental aging, operating forces, etc.). We will be more than happy to help you select the right test methods for your specific application.

We have universal testing machines that allow for loads up to a maximum force of 100 kN and accordingly make it possible to test high-strength materials as well.

|

Relevant Standards: |